(Construction) - Japanese construction company Kajima has established a system to eliminate the amount of residual and returned concrete at construction sites.

|

| Japan’s Kajima develops system to reduce residual concrete at construction site. |

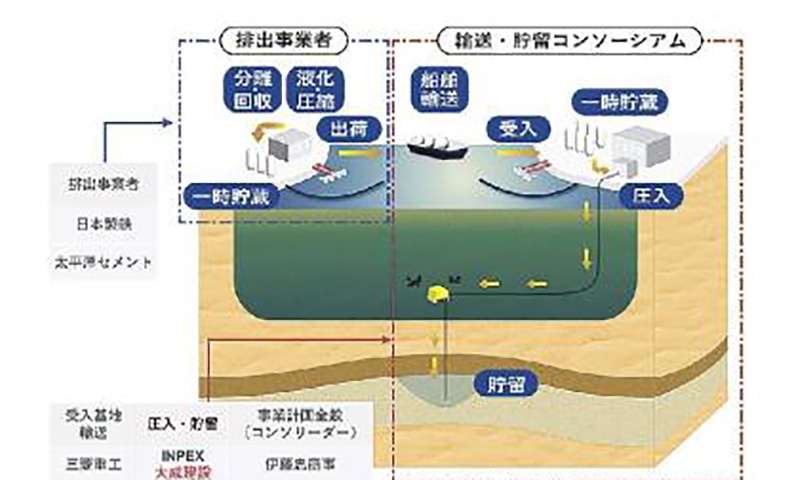

The system utilizes existing muddy water treatment facilities and uses liquefied carbon dioxide gas in the separation and treatment process. The residual and returned concrete is separated into reusable coarse aggregate, treated soil that has been neutralized by absorbing and fixing carbon dioxide, and water with a low pH and turbidity that can be discharged. Separate the residual/returned aggregate from the CO The system simultaneously realizes the reduction of residual/returned concrete and CO2 emissions.

The system consists of a turbid water treatment system, which is generally installed at large-scale sites, with the addition of a vibrating sieve. After fresh concrete is completely separated into mortar and coarse aggregate as it passes over the sieve, the coarse aggregate is discharged.

The mortar collected in the water tank below the sieve is stirred to form suspended water. The water is then sent to an existing turbid water treatment system. The treated soil, a mixture of calcium carbonate and fine aggregate, which has been neutralized by absorbing and fixing CO2 through treatment with liquefied carbon dioxide gas, is separated from the treated water.

The system was constructed and tested at a construction site in Ichikawa City, Chiba Prefecture. It was confirmed that the system can separate reusable coarse aggregate from residual and returned concrete and treated soil that has been neutralized by absorbing and fixing CO2. In the drainage of the treated water, they were able to lower the pH and turbidity until the water was ready to be discharged. The company will continue to improve the separation capability and apply the technology on site, aiming for practical use by the end of this year. The company is also considering the effective use of treated soil and the use of exhaust gas from heavy machinery instead of liquefied carbon dioxide gas. (2022/04/27)

The Daily Engineering and Construction News of Japan

Theo